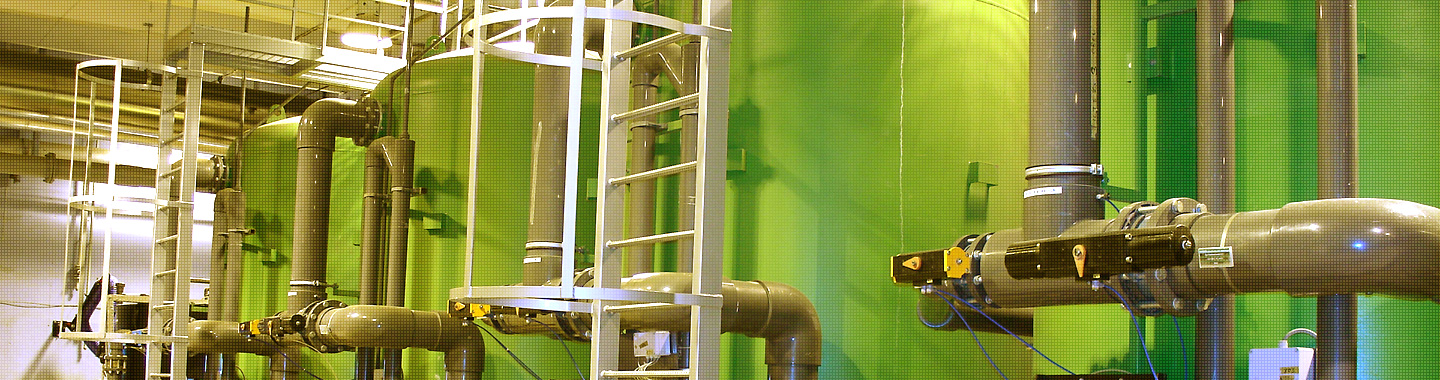

INDUSTRIAL EFFLUENT TREATMENT PLANTS

- Aerobic & Anaerobic effluent treatment plants

- Biological Sewerage treatment plants

- Diffused aeration system

- Chemical Oxidation of high COD effluent

- Colour removal for textile effluents

- Pressure sand filters & Carbon filters

- Tertiary Treatment Plants

- Tilted Plate Interceptor for Oil Separation

- Dissolved Air Flotation for emulsified / oily waste

- Sludge Thickeners, Rake Arm Clarifiers

- Water reclamation and reuse

- Ultra filtration plants

- Nano filtration plants

- Reverse Osmosis Plant

- Sprinkler type to enhance the evaporation rate in Solar Evaporation pond for disposal of High TDS effluent & RO Rejects

MULTIPLE EFFECT EVAPORATOR

A Multiple Effect Evaporator, as defined in chemical engineering, is an apparatus for efficiently using the heat from steam to evaporate water.

Enviro Chem Engineers & Consultants India Pvt. Ltd. is in a position to provide supply of equipment by providing various equipments for evaporating large volumes of water such as salt production & water desalination in all industrial applications.

Features:

- Evaporators may be built with an arbitrarily large number of stages. Evaporators with more than four stages are rarely practical except in systems where the liquor is the desired product such as in chemical recovery systems where up to seven effects are used.

- Multiple effect evaporation commonly uses sensible heat in the condensate to preheat liquor to be flashed. In practice the design liquid flow paths can be somewhat complicated in Order to extract the most recoverable heat and to obtain the highest evaporation rates from the equipment.